Customized products work better for consumers because they meet their specific needs. Tomato nutrition is no different. Customized fertility programs are effective because they meet the specific nutrient requirements of the tomato crop. Fertigation is a good way to implement a customized nutrition program for commercial tomato production, especially when liquid fertilizers are used. We’ve updated this blog post in 2022 to provide more information on different fertigation treatments on commercial tomato production, and their effects on yields and quality.

Fertilizer Challenges Facing Tomato Growers

Flavor, as well a yield, is an important concern for tomato growers. High relative concentrations of sugars and acids result in a more flavorful fruit. Brix levels measure the Total Soluble Solid content, which is mainly sugars. Higher Brix readings indicate good soil fertility. Balanced phosphorus and potassium levels in the soil will ensure more even Brix development in the plant. In addition, higher levels of potassium in the plant also increases the acidity of the fruit. The best, most flavorful, combination in the fruit is a high sugar and high acid content.

Depending on soil type, 90-98% of total soil potassium is unavailable. Feldspars and micas are clays that contain large amounts of potassium, but plants cannot use the nutrient if it is trapped between the layers of those clays. In persistently dry soils, potassium remains unavailable, as there is no water film surrounding the soil particles. Over time, these minerals break down, and the potassium is released. However, this process is too slow to provide crops the amount of potassium needed for optimal yield. Typically, only 1-2% conventional potassium fertilizers applied to the soil is available at one time.

Micronutrient deficiencies can be difficult to recognize because they resemble other problems. For instance, in tomatoes, manganese deficiency produces yellowing, which can look like a sulfur deficiency or even be confused with nitrogen deficiency. Often tissue testing can determine the cause, but it is best to have a good soil test so any problems can be addressed ahead of seeing nutrient deficiency symptoms.

Fertigation Treatments on Commercial Tomatoes

Many tomato growers use drip systems to provide plant nutrition through irrigation water, a process known as fertigation. Drip systems can accommodate both water-soluble granules and liquid fertilizers, but there are some definite advantages to using liquid over water-soluble granular formations.

Flexibility and Uniformity

Fertigation allows the grower to apply smaller applications on a frequent basis with greater uniformity. Conventional fertilizer programs can be hit or miss because they usually consist of two or three applications per season. Depending on a plant’s stage of development, it may receive too much or too little fertilizer, or it may not be able to utilize the nutrients at all.

Nutrient Uptake

Fertigation improves nutrient uptake because it targets the active root zone; plants have easy access to the nutrients they need. Application rates can also coincide with a crop’s nutrient needs at different growth stages. For instance, growers can start with smaller doses at planting, increase the dose during the vegetative stage, and then decrease the dose as the crop nears the fruiting stage and maintain crop health at the end of a plant’s lifecycle.

Liquid Fertilizers vs Conventional Fertilizers in Fertigation Treatments for Tomatoes

This study performed by AgroLiquid showed fertigation treatments using liquid fertilizer have a greater impact on tomato yields than conventional treatments. For the experiment, researchers compared the effects of liquid and conventional fertigation treatments on the yield of fresh market ‘Beefsteak’ and ‘Roma’ type tomatoes. Let’s take a closer look at the details.

Experiment #1: Liquid vs Conventional Fertilizer on Roma and Beefsteak Tomatoes

Soil preparation included banding liquid fertilizer down the center of the plots or broadcasting dry fertilizer into the area. A swath of plastic mulch covered the center 2 ft. of each 5 ft. wide plot.

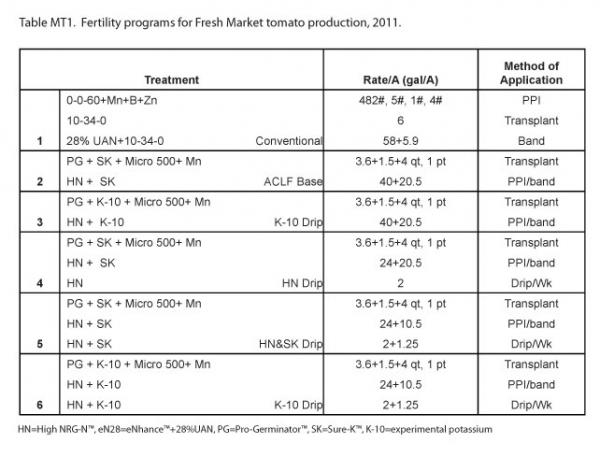

Growers doused the soil around each transplant with approximately 4.2 oz. of transplant solution (~300 GPA) which contained the fertilizers described in Table MT1. The rest only had water. For early season disease and insect management, Ridomil and Admire were added to the transplant water.

Drip applications started at early bloom and continued until mid-September. Eight weekly treatments occurred during the season. Upon maturity, ripe fruits were counted and weighed to determine yields. Spring rains delayed planting and harvesting, so a majority of the yields for all treatments occurred during the final portion of the season. Six harvests took place throughout the season; the initial harvest occurred on Aug. 13 and the last on Oct. 18.

Conclusions

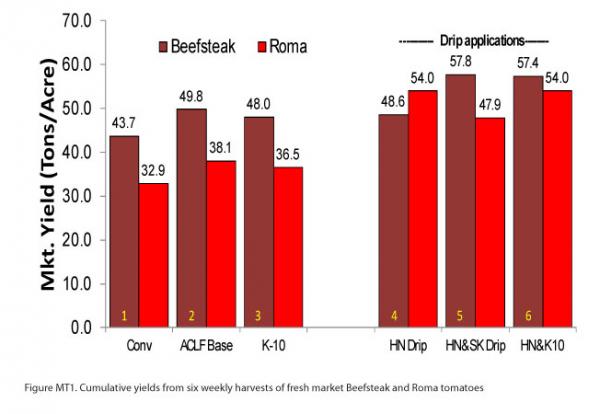

When 100% of the fertilizer was applied pre-plant, the AgroLiquid base program (Trt. #2, See Figure MT1) surpassed the conventional program (Trt. #1) for the yield of ‘Beefsteak’ and ‘Roma’ type tomatoes.

During the growing season, drip applications (Trt. #4-#6) supplied 40% of total nitrogen, and in some cases (Trt. #5 and #6), nearly half of the potassium. These changes in the application timing improved tomato yields without using any additional fertilizer when compared to the Agro-Liquid base program (Trt. #1). Table MT1 shows these changes in application timing and volumes.

Kalibrate, listed here as K-10 (Trt. #3 and #6), matched the performance of Sure-K® (Trt. #2 and #5) when it was used in a similar manner. Kalibrate has some winter storage advantages over Sure-K®.

Experiment #2: Kalibrate vs Potassium Thiosulfate on Canning Tomatoes

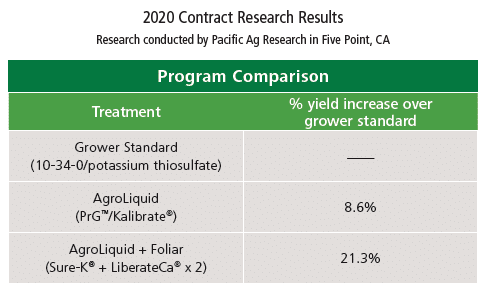

This trial measured the effects of different sources of potassium on the yield of canning tomatoes. We compared an application of 15 gallons of AgroLiquid’s Kalibrate with Nutriq Technology to a standard application of 50 gallons of potassium thiosulfate. In addition, this experiment compared the AgroLiquid treatment with an additional foliar application of potassium and calcium.

Conclusions

- One gallon of Kalibrate is equal to 10 lbs of applied K2O. The yields from the Kalibrate show that

using the ratio more than equals the amount of potassium in potassium thiosulfate or any other

form of potassium. - The tomatoes with the Kalibrate yielded 5 more tons per acre than for less than 1/2 the cost of

potassium thiosulfate. - AgroLiquid’s Nutriq Technology is a win-win for farmers, it out yields other forms of K,

and does is for much less cost.

Optimizing Tomato Fertilizers

To learn more about the effects of AgroLiquid fertilizer treatments on tomato yields and quality, take a look at our tomato research. If you’re interested in optimizing your commercial tomato yields and quality, talk with our experienced agronomists. We’ll use our knowledge and research to find the best fertilizer program for your tomatoes, according to your goals, budget, soil type, and climate.

Exact application needed for liquid agro

Hello Sultan. Is that a question or a comment?