Cutting-Edge Products Developed With Hands-On Research

Explore the North Central Research Station

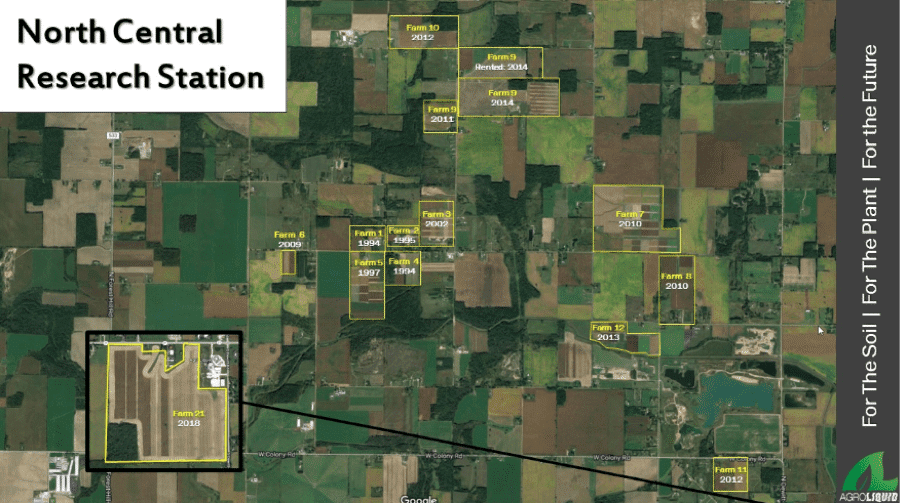

North Central Research Station (NCRS)

Our products are developed through scientific research conducted in real cropping conditions at our North Central Research Station (NCRS). With more than 1,400 tillable acres, we have the space and expertise to test our products in a variety of circumstances. It’s this combination of expert chemistry and in-the-field research that helps us develop the best products, and helps our customers get the best return on their fertilizer investment.

Laboratory conditions are ideal for developing high-efficiency fertilizer products, but they won’t show how these products work in real life conditions. That’s where the NCRS comes in. Our research facility allows us to test our products, as well as other crop inputs, and study the challenges that farmers face every year, including drought, disease, fungus, and, perhaps most important, yield.

Studying Your Crops in Real-Life Conditions

Working in real-life conditions allows us to study more variables than just fertilizer. It also allows us to see how real-life weather patterns, soil conditions, growing patterns, and other variables affect the performance of our crops and our products.

While the NCRS is the first farm to see our latest high-efficiency fertilizers, we test a variety of other variables as well, including:

- Irrigation and water distribution

- Effects of drought

- Fertilizer application methods

- Fertilizer and crop safety

- Impacts from disease and fungus

- Visible signs of nutritional deficiency

- High-efficiency liquid fertilizer compared to solid fertilizer

Community Outreach

Even when we’re involved in careful scientific studies, we never forget our surrounding community. The NCRS is not only our place to study the impacts of fertilizer, irrigation, and equipment, it’s also a place where our fellow farmers can learn more about the latest agricultural innovations. We regularly host farmers and agricultural industry professionals from across the United States at the NCRS, so they can see exactly what we do.