“Liquid Perks”:

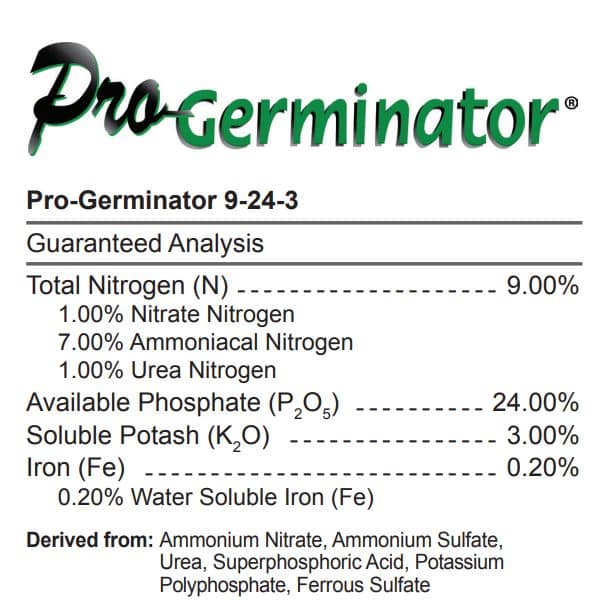

These are unique fringe benefits that are offered to our employees in addition to the traditional benefits. There are many, but a few of the more unique one’s are: annual allowance of AgroLiquid product, clothing and promo items; a library of over 500 items ranging from agronomy audio books to paperback enjoyment reading; an identity-theft assistance program; company asset auctions; and believe it or not, a week long Hawaii Trip!