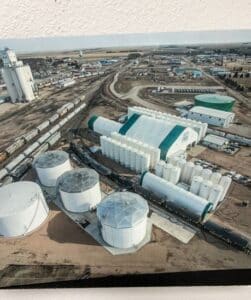

AgroLiquid has facilities across the country! Today we’re featuring our manufacturing and distribution center in Goodland, Kansas.

- Opened: 2001

- Acres: 12

- Staff: 14

Robert Rall has been the Goodland KS Site Manager since 2005.

Growth over time

In 2001, AgroLiquid built the facility, and in 2002, they brought in thirty 30,000 gallon fiberglass tanks. At the time, they were running one million gallons in storage.

Today, they have 6.7 million gallons of storage capacity.

“When I came here, I knew nothing about fertilizer,” Robert said. “I was a master painter for 27 years…now I look at what we’ve done in the last 19 years, and I think ‘wow.’ It’s been very busy and very rewarding career for sure.”

The team’s efforts have translated into increased output. For the last five years, the facility has manufactured and distributed 12 million gallons of fertilizer annually.

“In 2018 and 2019 we went to 15 million,” he said. “In May 2019, we did 53 truckloads out of here in one day, and we did a million gallons that week. Before the Stockton California plant came on line, we were delivering anywhere west of I-35 in North America.”

Production

The Goodland facility manufactures and distributes a variety of AgroLiquid products.

“High NRG-N is our biggest delivery, at 7.5 million gallons a year,” Robert said. “Pro-Germinator is our next, as we do three million gallons a year on that. Next up are Kalibrate and Access.”

Robert is happy with the expansion of the facility over the years.

“We had massive amounts of growth from 2001 to 2014 when we were adding onto the facility,” he said. “In 2008 we built a 13-tank containment. We started putting up 500,000 gallon bulk tanks, and we put up three of those in 2011. In 2013 we did another half million gallon tank plus a two-million gallon tank, and we hired more people. Then we got grant money and made the street concrete.”

He also takes great pride in the people who make up the Goodland facility.

“I have some of the best employees in the world,” he said. “Everyone has their role, but everybody cross trains. You’d be amazed at what happens here. Sometimes, we get 25 rail cars in one day. We can get it done in two days. Everyone has their own jobs, but when a big project comes in everyone gets together and gets it knocked out. It makes me proud.”

Stay tuned for our next facility feature!

2011 2015