How to Optimize Your Almond Fertilizer Program

Dylan Rogers, Sales Account Manager for AgroLiquid

There are many factors that will affect the yield potential of almond crops; some we can control and others we cannot. We can fight disease and insect pressure, but we cannot prevent it completely. One factor we do have complete control over, however, is our almond fertilizer program and ensuring we supply the trees with the nutrients they need to produce that high-yielding crop. We’re updated this blog post in 2023 to give you even more information to help your almond crops.

Soil Samples for Your Almond Crop

A great starting point for optimizing your almond fertilizer program is by assessing what you have in the soil. Looking at a current soil sample will give you an idea of what needs to be done in season to ensure adequate fertility for maximum yields.

There are multiple things to consider when reading a soil test. You may see that most or all of your nutrient levels read adequate or high; However, the ratios of some nutrients are more important than the levels. For instance, iron and manganese are antagonistic to each other. You may have adequate levels of both nutrients in your soil, but if the ratio is off, you may see symptoms of deficiency.

You need more iron than manganese in the soil. The ideal ratio is 2:1 iron to manganese. The closer this ratio gets to 1:1, the more likely you will see an iron deficiency in season. The ratio of phosphorus to zinc is also an important factor. A ratio of 10:1 phosphorus to zinc is the ideal balance between these two nutrients. If phosphorus levels get too high, it may induce a zinc deficiency. These are just two examples of many ratios that should be addressed in your soil. A soil sample will ensure you have the information you need to get off on the right foot to maximizing this season’s yield.

Our team can help you with soil sampling

Learn more

Ideal Almond Fertilizer During Bud Break, Pink Bud, Bloom

During the period in which fruit buds are swelling, the trees are also working below the soil surface. This is an important time to optimize your almond fertilizer program. A new flush of feeder roots are pushing out, and having an adequate supply of phosphorus and soil moisture is critical in the development of these new roots. Choosing a phosphorus fertilizer that is protected from tie-up in the soil ensures the most return on this investment. Following bud swell and new root development will be bud break, a period in which flower and pollen development are crucial. These fruiting buds that will become flowers are the fate of this season’s crop, so we do everything possible to protect and ensure their viability. Foliar applications of phosphorus, calcium, zinc, boron, and molybdenum can be beneficial, as they play important roles in all aspects regarding pollen.

Fertilizer During Almond Fruit Development

The almond tree’s highest demand for nitrogen and potassium is from fruit set to harvest. Supplying these two nutrients in adequate amounts is crucial to achieve a high yielding crop. Nitrogen is a critical component of many plant parts and functions. It is needed to produce chlorophyll, DNA and RNA, and to synthesize amino acids. Studies have shown that for every 1,000 pounds of kernels removed, about 85 pounds of nitrogen are removed after accounting for fertilizer inefficiencies. Choosing a nitrogen fertilizer that is low in salts and less likely to leach or volatilize will ensure optimum uptake by the tree and give you the most return on your fertilizer investment.

Potassium is also very important for many plant functions and is required in large amounts. Potassium plays a major role in the opening and closing of stomata, photosynthesis, translocation of sugars, and many other plant processes. Studies show that for every 1,000 pounds of kernels removed, around 90 pounds of K20 are removed. There are some important things to take into consideration when choosing a potassium source. Almonds are very sensitive to salts such as chlorides and hydroxides. Some fertilizers can even be toxic if applied at higher rates. Choose a potassium source that is free of chlorides and hydroxides to ensure maximum uptake and to minimize potential for crop injury.

AgroLiquid’s potassium fertilizers are designed to minimize chlorides and hydroxides in the soil

Learn more

Case Study in Almond Fertilizer Optimization: California

Almond acres have been steadily growing in California since the 1980s, and the crop is now California’s number one exported agricultural commodity. With over 2.4 million acres of trees planted, California grows over 85% of the world’s almonds. Virtually all commercially harvested almonds produced in the U.S. come from California. Most of that is due to the climate: warm, dry summers and cool, rainy winters are key to setting the tree up for success. But we know it takes more than a temperate climate to maximize a crop’s potential.

AgroLiquid crop nutrition can be a valuable tool in producing an abundant and quality almond crop. In an effort to determine the best sources, rates, timings and methods of application for this important crop, for the past two years, AgroLiquid has invested in and run a full-scale research trial in almonds in California. These trials can help us learn what works and what doesn’t in order to optimize almond fertilizer programs.

Testing Potassium Fertilizer in Almonds

Almonds are the perfect crop to test our Nutriq Technology, given how much potassium is needed to produce a crop. AgroLiquid’s proprietary technology allows us to chelate/encapsulate nutrients within the sweet spot – not too loose, but not too tight. Our two year almond research trial has been conducted by Barat Basabri of Basabri Ag Research in Newman, CA.

Trial details:

Each plot consists of five trees and was replicated six times across the orchard. Throughout the growing season, 50 gallons per acre (ga/A) of UAN-32 is applied as a constant in every plot.

Plot 1 (Conventional grower standard):

• 10-34-0 applied at 37.5 ga/A

• Potassium thiosulfate applied at 40 ga/A

• EDTA Zinc (Zn) applied four times during the season for a total of 2 ga/A

Plot 2:

• Actagro’s Structure® applied at a rate of 25 ga/A

• Potassium thiosulfate applied at 40 ga/A

• EDTA Zinc (Zn) applied four times during the season for a total of 2 ga/A

Plot 3:

• AgroLiquid’s PrG™ applied at 15 ga/A

• Potassium thiosulfate applied at 40 ga/A

• EDTA Zinc (Zn) applied four times during the season for a total of 2 ga/A

Plot 4:

• AgroLiquid’s PrG applied at 15 ga/A

• AgroLiquid’s Kalibrate™ at a rate of 13.2 ga/A

• EDTA Zinc (Zn) applied four times during the season for a total of 2 ga/A

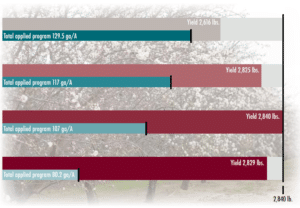

The results of the two-year averages are as follows. Plot 1: The “Grower Standard” of 10-34-0 + Potassium thiosulfate yielded an average of 2,616 lbs. per acre. The second plot where Structure® was used in place of 10-34-0 + Potassium thiosulfate, yielded a two-year average of 2,825 lbs./acre. The third plot was AgroLiquid’s PrG + Potassium thiosulfate which yielded an average of 2,840 lbs./acre. The final plot was a full AgroLiquid program using both PrG + Kalibrate which yielded a two-year average of 2,829 lbs./acre. Yield results in the last three plots were comparable.

Optimizing your almond fertilizer program this season will help achieve maximum yield potential. Again, there are multiple factors that are out of our control so taking advantage of the factors we can control is important. Choose your fertilizers this season with plant and soil health in mind to maximize your return on investment.