By Jerry Wilhm, Ph.D., Research Lead, North Central Research Station

What if for every 10 crops grown with AgroLiquid crop nutrients, you got an 11th crop on top of the previous 10? Intrigued? Read on, I will explain.

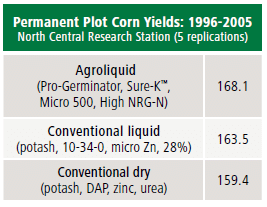

Those familiar with research at the North Central Research Station (NCRS) will recognize our Permanent Plots trials, where the same fertilizer programs are used in the same plots in a corn-soybean rotation. The first of these plot trials ran from 1996 to 2005 and shows results from a single field experiment. Looking at the results, the AgroLiquid program had a higher average yield despite lower pounds per acre of actual nutrients applied, and did not have extra application trips of dry fertilizer.

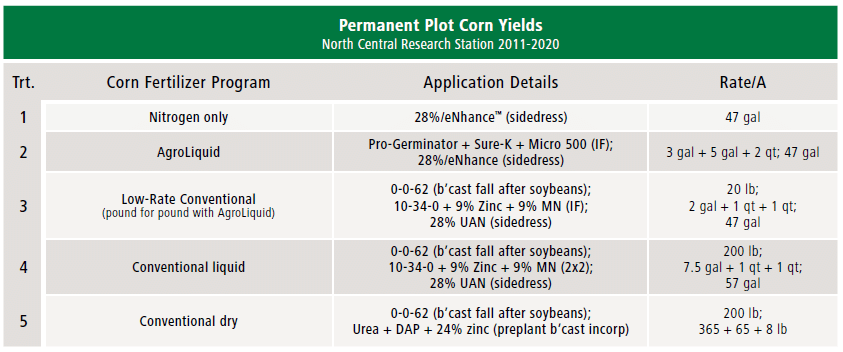

In 2011, another Permanent Plot test was set up on a different farm at the NCRS. This farm was new to the NCRS and the landowner had not grown corn there for many years. A yield goal of 170 bu/A was set and, as before, different fertilizer programs were developed to apply a 180-30-60 program of N-P2O5-K2O. It was felt that 170 Bu/A would be a good target based on production on other farms, but – spoiler alert – we were in for a surprise. The treatments were similar to those of the ’96-’05 plots, with a couple additional treatments:

- Full AgroLiquid program

- Conventional liquid (plus potash for potassium)

- Conventional dry (all dry fertilizers applied broadcast)

- Nitrogen only (to measure the effects of the P, K and micronutrients applied)

- Conventional fertilizers, but at the same reduced rate of applied nutrients as with the AgroLiquid treatment

The treatments and rates are in the table below:

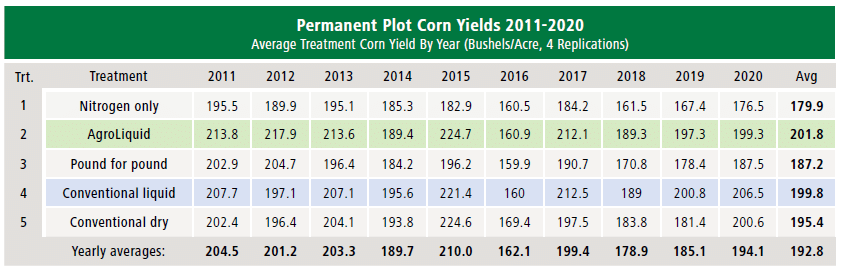

The field layout had a corn site next to a soybean site, and the treatments would rotate from site to site into the same plots each year. In the end, there were ten years of corn yields and ten years of soybean yields, all with four replications of treatments. Individual plots were 6 rows by 210 feet long. The corn yields appear in the following table:

- Yields were much higher than the 170 bu/A yield goal, even for the nitrogen only. So the no corn history threw us off, but the treatment rates were not adjusted, and remained the same for all ten years.

- The highest average yield was with AgroLiquid and was slightly higher than that of the conventional liquid treatment. But there were extra application trips for potash.

- The AgroLiquid yield was statistically higher than that of the conventional dry treatment. (Note: The Least Significant Difference (LSD) value is based on statistical analysis of the data, and if a yield difference between treatments is greater than the LSD value, then it is considered to be a “statistically significant difference.” This is important as it takes variability of data into consideration. The value is fairly low, but it indicates similar trends over 10 years. There are 40 numbers going into each average.)

- The AgroLiquid yield was significantly higher than that of the “pound for pound” rate of conventional fertilizers. This demonstrates the importance of high-efficiency formulations. The low-rate conventional treatment yielded pretty close to the full rate conventional treatments for the first two years, but started to decline in the third year.

It was also observed that the AgroLiquid treatment yielded far higher than did the full-rate conventional programs in the first three years, then yields became closer after that. NCRS researchers believe because this was the first application of AgroLiquid to this soil, the corn responded particularly well to the product features, such as protected nutrients, nutrient slow release and micronutrient balance. Additionally, the AgroLiquid treatment used a reduced rate of UAN with the addition of eNhance™. Again, we designed this program for a 170 bu/A yield goal, and actual yields far exceed that. So the

corn enjoyed the premium fertilizer input and got off to a good start, but became more equal, but sustainable, after that.

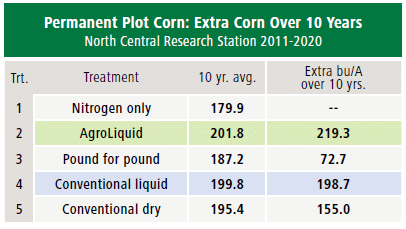

So what about the eleventh ‘bonus’ corn crop? The table shows the extra corn produced over 10 years compared to Nitrogen only. So by using Pro-Germinator, Sure-K and Micro 500, an extra 219.3 bu/A was produced. This is like a whole extra year of corn produced per acre. Actually more!

The AgroLiquid Advantage

Is AgroLiquid sustainable? Meaning, will it continue to perform over time? As you can see from our long-term research, the answer is: yes it will. Finding the answers to these questions is why AgroLiquid remains committed to replicated field trial and hands-on experience from the North Central Research Station and throughout North America. Armed with the knowledge and confidence that comes with this extensive research, our Researchers, Agronomists and Sales Team are able to make scientifically based

recommendations to sustainably optimize yield potential. You can find all of our research results on our website at research.agroliquid.com.

Your Guide to ✅ Precision Corn Nutrition ✅ Better ROI

Yields. Inputs. Soil tests. N-P-K. Micronutrients. Climate. Economy.

Setting the stage for a successful corn harvest can be difficult in an incredibly complex agricultural environment.